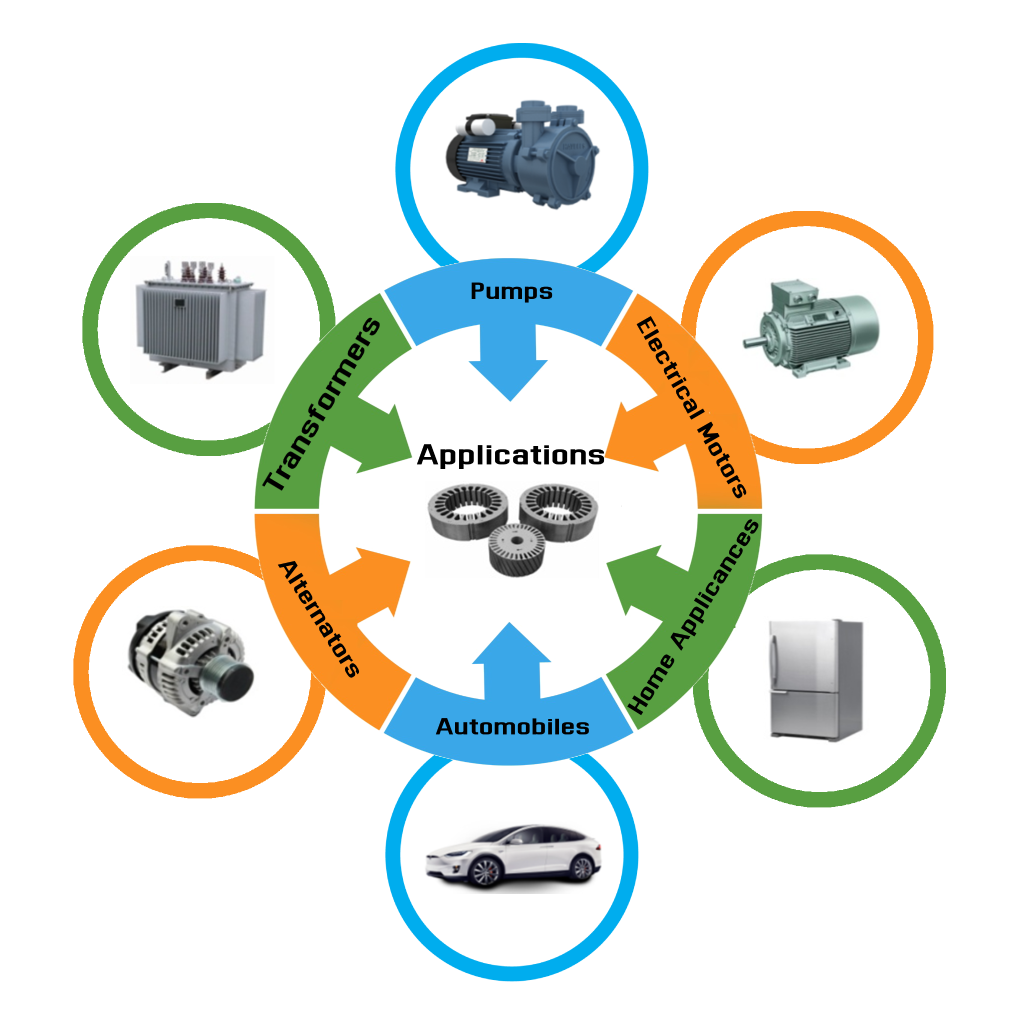

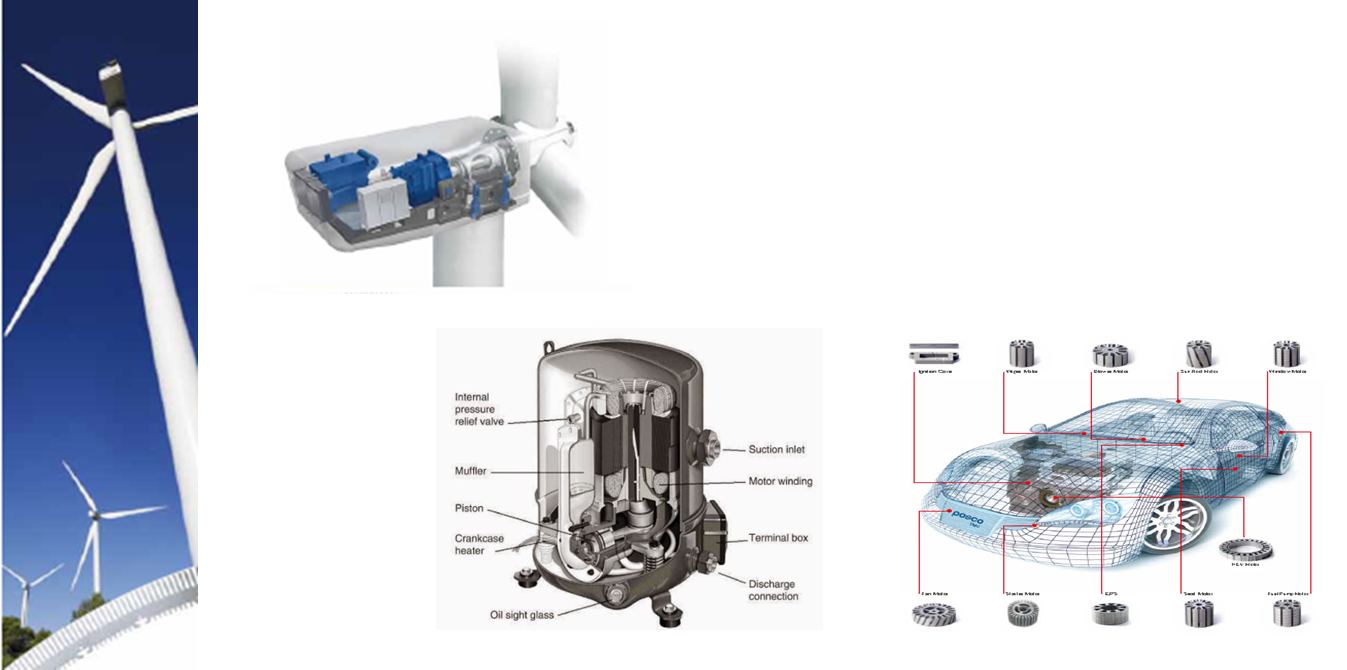

The non-oriented electrical steel features even magnetic properties in the rolling direction and in other directions. They are widely used for iron core materials of rotating machines ranging from large-size power generators to small-size precision electric motors, which are used in variety of applications like home appliances, HEV/EV traction motors, large generators, industrial motors Etc. They are also desirable for iron core of small-size power transformers.

Specification & Properties

| Grade | Thickness mm (Inch) | Density (Kg/dm3) | Core Loss Max. (W15/50) | Magnetic Flux Density Min. T (B50) | Lamination Factor, Min (%) | ||

|---|---|---|---|---|---|---|---|

| POSCO | Equivalent to IS Grade | Watt/Kg | Watt/lb | ||||

| 35PN230 | 35C230 | 0.35 (0.0138) | 7.60 | 2.30 | 1.04 | 1.62 | 95 |

| 35PN250 | 35C250 | 7.60 | 2.50 | 1.13 | 1.62 | ||

| 35PN270 | 35C270 | 7.65 | 2.70 | 1.22 | 1.62 | ||

| 35PN300 | 35C300 | 7.65 | 3.00 | 1.36 | 1.62 | ||

| 35PN360 | 35C360 | 7.65 | 3.60 | 1.63 | 1.63 | ||

| 35PN440 | 7.70 | 4.40 | 1.99 | 1.65 | |||

| 50PN290 | 50C290 | 0.50 (0.0197) | 7.60 | 2.90 | 1.32 | 1.62 | 96 |

| 50PN310 | 50C310 | 7.65 | 3.10 | 1.41 | 1.62 | ||

| 50PN350 | 50C350 | 7.65 | 3.50 | 1.59 | 1.62 | ||

| 50PN400 | 50C400 | 7.65 | 4.00 | 1.81 | 1.63 | ||

| 50PN470 | 50C470 | 7.70 | 4.70 | 2.13 | 1.64 | ||

| - | 50C530 | 7.75 | 5.30 | 2.41 | 1.65 | ||

| 50PN600 | 50C600 | 7.75 | 6.00 | 2.72 | 1.66 | ||

| 50PN700 | 50C700 | 7.80 | 7.00 | 3.17 | 1.70 | ||

| 50PN800 | 50C800 | 7.85 | 8.00 | 3.63 | 1.70 | ||

| 50PN1000 | 50C1000 | 7.85 | 10.00 | 4.53 | 1.70 | ||

| 65PN400 | 65C400 | 0.65 (0.0256) | 7.65 | 4.00 | 1.81 | 1.65 | 97 |

| 65PN470 | 65C470 | 7.70 | 4.70 | 2.13 | 1.65 | ||

| 65PN600 | 65C600 | 7.75 | 6.00 | 2.72 | 1.66 | ||

| 65PN700 | 65C700 | 7.80 | 7.00 | 3.17 | 1.70 | ||

| 65PN800 | 65C800 | 7.85 | 8.00 | 3.63 | 1.70 | ||

| 65PN1000 | 65C1000 | 7.85 | 10.00 | 4.53 | 1.70 | ||

Note : The above test is conducted in accordance to IEC60404-2 / JIS C2550-2000 / IS : 648 : 2022. W15/50 indicates the core loss at magnetic flux density of 1.5T & frequency of 50 Hz .

| Grade | Thickness mm (Inch) | Tensile Strength (N/mm2) | Yeild Strength (N/mm2) | Elongation % | Hardness (HV1) | Lamination Factor (%) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| POSCO | Equivalent to IS Grade | L | C | L | C | L | C | |||

| 35PN230 | 35C230 | 0.35 (0.0138) | 535 | 545 | 393 | 403 | 19 | 20 | 216 | 97.5 |

| 35PN250 | 35C250 | 522 | 539 | 370 | 385 | 19 | 21 | 214 | ||

| 35PN270 | 35C270 | 470 | 490 | 350 | 360 | 21 | 23 | 190 | ||

| 35PN300 | 35C300 | 456 | 469 | 336 | 351 | 21 | 23 | 188 | ||

| 35PN360 | 35C360 | 450 | 470 | 310 | 330 | 23 | 25 | 170 | ||

| 35PN440 | 405 | 415 | 273 | 285 | 27 | 29 | 155 | |||

| 50PN290 | 50C290 | 0.50 (0.0197) | 510 | 530 | 370 | 386 | 23 | 25 | 195 | 98 |

| 50PN310 | 50C310 | 483 | 505 | 355 | 361 | 25 | 28 | 189 | ||

| 50PN350 | 50C350 | 470 | 489 | 344 | 354 | 25 | 28 | 185 | ||

| 50PN400 | 50C400 | 465 | 482 | 352 | 365 | 27 | 30 | 183 | ||

| 50PN470 | 50C470 | 420 | 430 | 275 | 285 | 34 | 36 | 155 | ||

| - | 50C530 | 410 | 420 | 270 | 280 | 37 | 38 | 135 | ||

| 50PN600 | 50C600 | 395 | 405 | 268 | 278 | 37 | 39 | 130 | ||

| 50PN700 | 50C700 | 385 | 395 | 265 | 275 | 38 | 39 | 125 | ||

| 50PN800 | 50C800 | 375 | 385 | 260 | 270 | 39 | 40 | 118 | ||

| 50PN1000 | 50C1000 | 370 | 380 | 250 | 260 | 40 | 41 | 113 | ||

| 65PN400 | 65C400 | 0.65 (0.0256) | 480 | 485 | 335 | 340 | 29 | 30 | 180 | 98 |

| 65PN470 | 65C470 | 425 | 435 | 290 | 305 | 34 | 36 | 155 | ||

| 65PN600 | 65C600 | 390 | 395 | 270 | 280 | 35 | 37 | 130 | ||

| 65PN700 | 65C700 | 380 | 390 | 265 | 275 | 36 | 38 | 121 | ||

| 65PN800 | 65C800 | 370 | 385 | 260 | 270 | 38 | 40 | 116 | ||

| 65PN1000 | 65C1000 | 370 | 380 | 250 | 260 | 41 | 42 | 110 | ||

Note :1. L : Specimens taken longitudinal to the rolling direction, C: Specimens taken transverse to the rolling direction.

2. Specification with C-6H coating are used for lamination factor test.

| Width mm (in) |

Thickness mm (in) |

Thickness Tolerance mm (in) |

Thickness deviation in transverse direction mm (in) |

Width Tolerance mm (in) |

Camber (Length: 2m) mm (in) |

|---|---|---|---|---|---|

| 1,000 (39.37) and under | 0.35 (0.0138) 0.50 (0.0197) 0.65 (0.0256) |

±0.028 (0.00110) ±0.040 (0.00158) ±0.039 (0.00154) |

0.020 (0.0008) and under 0.020 (0.0008) and under 0.030 (0.0012) and under |

+1.0 (0.0394)

– 0.0 |

2.0 (0.0787) and under |

| 1,000 (39.37) and over | 0.35 (0.0138) 0.50 (0.0197) 0.65 (0.0256) |

±0.028 (0.00110) ±0.040 (0.00158) ±0.039 (0.00154) |

0.020 (0.0008) and under 0.020 (0.0008) and under 0.030 (0.0012) and under |

+1.5 (0.0591)

- 0.0 |

| POSCO Coating Types → | General (Chromate base) |

Eco-friendly (Phosphate base) |

Remarks | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C-6H | C-9H | NS | NM | NR | NT | |||||||

| Equivalent ASTM Type | C-5 Type | C-5 Type | C-5 Type | C-5 Type | C-6 Type | C-6 Type | - | |||||

| Composition | Organic + Inorganic | Organic + Inorganic | Organic + Inorganic | Organic + Inorganic | Organic + Inorganic + Filler | Organic + Inorganic + Filler | - | |||||

| Surface Characteristic | Smooth & Thin Coating | Smooth & Mid-Thick Coating | Smooth & Thin Coating | Smooth & Mid-Thick Coating | Smooth & Thick Coating | Smooth & Thick Coating | - | |||||

| Thickness (in um) | 0.4~0.6 | 1.0~1.2 | 0.4~0.6 | 1.0~1.2 | 2.0~4.0 | 4.0~8.0 | - | |||||

| Resistivity (IR) (in Ωcm2/sheet) |

Before SRA | ≥0.5 | ≥5.0 | ≥0.5 | ≥5.0 | ≥30.0 | ≥50.0 | IR test as per ASTM A 717 | ||||

| After SRA | 0.1 | 0.5 | 0.1 | 2.5 | SRA Not Accepted | SRA Not Accepted | SRA condition : 750°C × 2hrs. In DX rich gas | |||||

| Lamination Factor (%) |

98.0 | 98.0 | 98.0 | 98.0 | 97.5 | 97.0 | JIS C 2550, 1.0MPa ±0.05 in Pressure, Specimen:0.5mmt |

|||||

| Heat resistance Flaking | Continuous | Not observed | Not observed | Not observed | Not observed | Not observed | Not observed | 155°C × 24hr in Air | ||||

| Short | Not observed | Not observed | Not observed | Not observed | Not Applicable | Not Applicable | 750°C × 2hrs. in DX rich gas | |||||

| Weathering (powdering) | Not observed | Not observed | Not observed | Not observed | Not observed | Not observed | 65°C, 95% humidity, 72 Hr | |||||

| Adhesion | Before SRA (Mandrel bend tester) |

10 mm (Φ) | 10 mm (Φ) | 10 mm (Φ) | 10 mm (Φ) | 10 mm (Φ) | 10 mm (Φ) | ISO 1519 | ||||

| After SRA (Cross cut tester) |

5B | 5B | 5B | 5B | Not Applicable | Not Applicable | ASTM D3359B [OB (poor) ~ 5B (excellent)] |

|||||

| Resistance to refrigerants | Change of surface | Not observed | Not observed | Not observed | Not observed | Not Applicable | Not Applicable | R-134a/Freol @15C = 65g/100g (1300C, 21day, 0.45µm filter paper) | ||||

| Change of weight | Not observed | Not observed | Not observed | Not observed | Not Applicable | Not Applicable | ||||||

| Weldability | Good | Normal | Good | Normal | Normal | Normal | Current : 100 - 150A, Ar 99% flow: 10 - 20L/min, Speed: 0.25 - 0.50mpm | |||||

Note :1. Please designate surface insulation according to usage.Regarding coating properties,please contact us.

2. The coating thickness value and the resistivity is typical value, not guaranteed.