Hot-dip galvanized steel products are now being used in a wide range of automobiles, electrical equipments and other industrial machinery as well as in civil engineering and construction. Since hot-dip galvanized steel products are characterized in excellent formability, weldability, paintability as well as anit corrosion, they can meet the high quality requirements of the users. POSCO Maharashtra will continue to make its best efforts to produce much superior products.

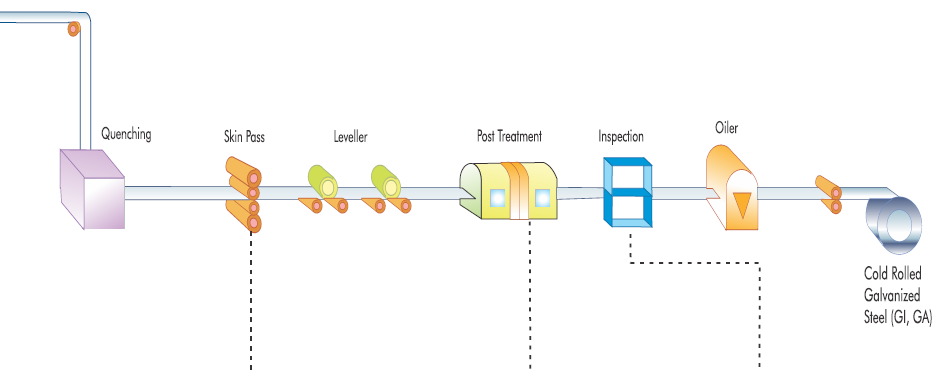

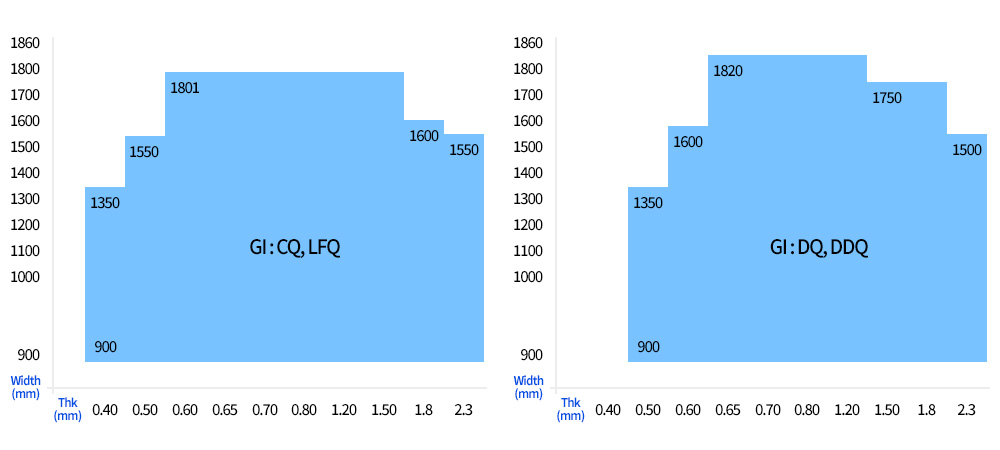

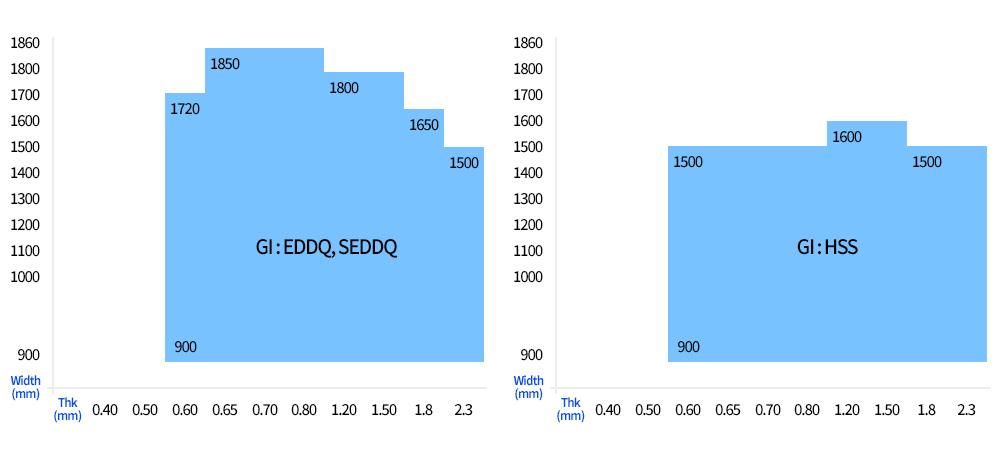

POSCO Maharashtra’s modernized vertical 450m length Continuous Galvanizing Line (CGL) can produce India’s widest (1,860mm), strongest (780DP steel), various grade Best Quality Steel which are then confirmed with various international standards such as IS, JFS, JIS, ASTM, EN/DIN, KS Etc.

| Classification | POSCO Maharashtra Continuous Galvanizing Line (CGL) | |||

|---|---|---|---|---|

| Date of Operation | May, 2012 | |||

| Capacity (Ton/year) | 450,000 | |||

| Available Size | Thickness (mm) | 0.35~2.30 | ||

| Width (mm) | 800~1,860 | |||

| Weight (Ton) | Max 30 | |||

| Coating Weight (g/m²) | GA | Both side 60~120 | ||

| GI | Both side 60~600 | |||

| Classification | POSCO Maharashtra Continuous Galvanizing Line (CGL) | |||

|---|---|---|---|---|

| Product Grade | Cummercial, Drawing, Deep Drawing, Extra Deep Drawing, Structural, High-strength Steel, BH, AHSS (DP590 & DP780) | |||

| Chemical Treatement | Oiling, Cr-Free, Phosphate, Chromoted 'Cr3+' | |||

| Inner Diameter (mm) | 508 (20")/610 (24") | |||

| Coil Weight | 5.0~25.0 MT | |||

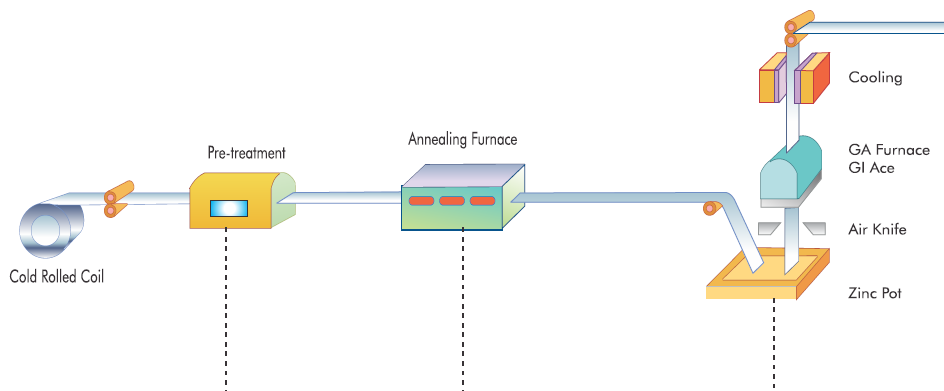

The main purpose of Electrolytic Cleaning is to be remove the lubricant oil and dirt left on cold rolled strip before annealing.

A steel sheet having a pre-treatment to secure for some mechanical characteristics after being re-crystallized during the annealing process.

Zn is coated onto the surface of a steel sheet after passing the annealing furnce in the Zinc Pot, and then the targeted coating weight is achived by spraying some high pressure air from the air knife.

In order to improve the mechanical properties, suppress yield point elongation, strip shape correction to the secure the flat shape, to the obtain desired roughness, the steel sheet should be passed through a skin pass mill.

In order to prevent any white rust which can occur on the surface due to activated zinc, to improve the corrosion resistance the surface is coated with Cr-free resin / chromate.

The equipment at the exit section are composed surface defect detector, Inspection table and Oiler equipment. The Product are inspect and judge systematically, whether such products are appropriate to client company or not.

The products are composed of various metal components and hove various mechanical properties in accordance with design standard, depending on various sizes and uses, such as a CQ, DQ, DDQ, EDDQ, Structural steel, HSS, AHSS and so forth.

| Classification | POSCO Specification (GI & GA) | EN | JIS | Characteristic | Application |

|---|---|---|---|---|---|

| Commercial Quality (CQ) | CGCC | EN-DX51D | JS-SGCC | Used for the parts requiring bending & simple forming | Bus Body, Fuel Tank, Drums, Furniture |

| Drawing Quality (DQ) | CGCD | EN-DX53D | JS-SGCD1 | Suitable for drawing parts | Automobile Inner Parts, General arts, Automobile Filter Housing |

| Deep Draw Quality (DDQ) | CGCN | EN-DX54D | JS-SGCD2 | Non Ageing quality used for Deep drawing parts with good Drawability | Automobile Inner & Outer parts like Roofs, Fenders, Bannet inner, Tunnel |

| Extra Deep Draw Quality (EDDQ) | CGCE | EN-DX56D | JS-SGCD3 | Ultra Low Carbon Steel with excellent deep draw quality | Automobile Inner & Outer parts like Side Panels, Tail Gate, Quarters, Automobiles Fuel Tanks |

| Super Extra Deep Draw Quality (S-EDDQ) | CGCX | EN-DX57D | - |

| Grade | Class | 0.2% YS, Mpa Spec. Max |

TS, Mpa Spec. Min |

El % Spec. Min |

|---|---|---|---|---|

| CQ | GI/GA | 280 | 270 | 33/31 |

| DQ | GI/GA | 240 | 270 | 37/35 |

| DDQ | GI/GA | 210 | 270 | 41/39 |

| EDDQ | GI/GA | 180 | 270 | 43/31 |

| S-EDDQ | GI/GA | 160 | 260 | 45 |

| Classification | POSCO Specification | EN | JIS | Characteristic | Application |

|---|---|---|---|---|---|

| Bake Hardening Steel (BH) | PGY180B(GI) PAY180B(GA) PGY210B(GI) PAY210B(GA) |

HX180BD+Z HX180BD+ZF HX220BD+Z HX220BD+ZF |

- | This is the high strength material in which yeild strenghth is increased after backing to become more dent resistance & higher formability | Automobile outer parts like Hood & Doors |

| HSLA (High Strength Low Alloy Steel) | CGCHS260Y CGCHS300Y CGCHS340Y CGCHS380Y CGCHS420Y |

HX260LAD HX300LAD HX340LAD HX380LAD HX420LAD |

SGC340 - SGC400 SGC440 SGC490 |

This is the high strength material manufactured by adding precipitation hardening elements to low Carbon Steel. Used in automobile mainly for rainforcing elements | Kinds of Member-Reinforcing Materials |

| IF HSS Steel | CGCHS35E CGCHS40 CHCHS45E |

HX220YD HX260YD - |

- | This is ultra-low carbon steel with special elements such as Ti added. it has high elongation rate and used in automobile where high strength and deep drawability requiered. | Automobile outer parts like Hood, Automobile Inner Parts, Floor, Reinforcement |

| Dual Phase (DP) | CGCHS60DP CGCHS80DP |

HCT590X HCT780X |

- | This is high strength and high formability properties by its duel phase structure consisting of micro ferrite & martensite. | Kinds of Member-Reinforcing Materials |

| Grade | Guaranteed Value | Class | 0.2% YS, Mpa Spec. Max |

TS, Mpa Spec. Min |

El % Spec. Min |

|---|---|---|---|---|---|

| PGY180B(GI) PAY180B(GA) |

YS | GI/GA | 180 | 270 | 40 |

| PGY210B(GI) PAY210B(GA) |

YS | GI/GA | 210 | 340 | 34 |

| CGCHS260Y | YS | GI/GA | 260 | 350 | 28 |

| CGCHS300Y | YS | GI/GA | 300 | 380 | 22 |

| CGCHS340Y | YS | GI/GA | 340 | 410 | 20 |

| CGCHS380Y | YS | GI/GA | 380 | 460 | 18 |

| CGCHS420Y | YS | GI/GA | 420 | 490 | 16 |

| CGCHS35R | TS | GI/GA | 186 | 340 | 35 |

| CGCHS40 | TS | GI/GA | 230 | 390 | 27 |

| CGCHS45 | TS | GI/GA | 275 | 440 | 27 |

| CGCHS35E | TS | GI/GA | 175 | 340 | 34 |

| CGCHS40 | TS | GI/GA | 215 | 390 | 30 |

| CHCHS45E | TS | GI/GA | 255 | 440 | 27 |

| CGCHS60DP | TS | GI/GA | 340 | 590 | 20 |

| CGCHS80DP | TS | GI/GA | 450 | 780 | 16 |

Notes :

The product standards are for reference. Please be sure to confirm the recent standards when making orders with Technical Services.

| Caoting Weight (GSM) | Average value of Double-sided, Triple Spot Method (GSM) | Average value of Double-sided, Single Spot Method (GSM) | KS D 3506 | JIS G 3302 | POSCO |

|---|---|---|---|---|---|

| 60 | 60 | 51 | (Z06), F06 | (Z06), F06 | K060, S060 |

| 80 | 80 | 68 | Z08, F08 | Z08, F08 | K080, S080 |

| 100 | 100 | 85 | Z10, F10 | Z10, F10 | K100, S100 |

| 120 | 120 | 102 | Z12, F12 | Z12, F12 | K120, S120 |

| 180 | 180 | 153 | Z18, (F18) | Z18, (F18) | K180 |

| 200 | 200 | 170 | Z20 | Z20 | K200 |

| 220 | 220 | 187 | Z22 | Z22 | K220 |

| 250 | 250 | 213 | Z25 | Z25 | K250 |

| 275 | 275 | 234 | Z27 | Z27 | K275 |

| 350 | 350 | 298 | Z35 | Z35 | K350 |

| 450 | 450 | 383 | Z45 | Z45 | K450 |

| 550 | 550 | 510 | - | - | - |

| Thickness/Width | 800≤w<1,000 | 1,000≤w<1,250 | 1,250≤w<1,600 | 1,600≤w≤1,800 |

|---|---|---|---|---|

| 0.35<t<0.40 | ±0.05 | ±0.05 | ±0.06 | - |

| 0.40≤t<0.60 | ±0.06 | ±0.06 | ±0.07 | ±0.08 |

| 0.60≤t<0.80 | ±0.07 | ±0.07 | ±0.07 | ±0.08 |

| 0.80≤t<1.00 | ±0.07 | ±0.08 | ±0.09 | ±0.10 |

| 1.00≤t<1.25 | ±0.08 | ±0.09 | ±0.1 | ±0.12 |

| 1.25≤t<1.60 | ±0.1 | ±0.11 | ±0.12 | ±0.14 |

| 1.60≤t<2.00 | ±0.12 | ±0.13 | ±0.14 | ±0.16 |

| 2.00≤t≤2.30 | ±0.14 | ±0.15 | ±0.16 | ±0.18 |

| Edge Type | Width | Tolerances Using Cold Rolled Steel Sheet |

|---|---|---|

| Mill Edge | Under 1,250 | +7,0 |

| 1,250 and Over | +10,0 | |

| Slit Edge | Under 1,250 | +3,0 |

| 1,250 and Over | +4,0 |

The purpose of providing oil is to act as a lubricant, in order to avoid friction during drawing. The oil type may vary from customer tocustomer,depending upon their end applications, like rust preventive, lubricating, degreaseable, etc.

| Mode | Quantity (mg/m²) (BothSides) |

|---|---|

| Thin | 200~800 |

| Light | 800~1,800 |

| General | 1,800~3,000 |

| Heavy | 3,000~4,500 |

POSCO Cr-Free steel is POSCOs environment friendly Galvanized steel that does not include chromium 6+ or any other compound of chromium, known as harmful element to human body.

| Product | Coating Layer Structure | Characteristics | Appearance |

|---|---|---|---|

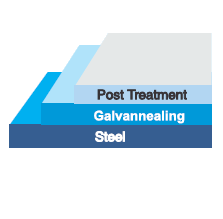

| GI (Galvanized Steel) |  |

While molten zinc solidifies on the surface of the steel sheet, normal zinc crystallisation is suppressed, creating fine crystals. The surface is flat and has a fine appearance after painting. Paintability is superior to regular products. |  |

| GA (Galvannealed Steel) |  |

By a thermal diffusion process, stell sheet and zinc react to produce an alloy layer. The weldability and paintability are superior to galvanized steel sheets. Fe in the alloy enhances corrosion resistance after coating. |  |

| Classification | Post Treatment | Quality Properties |

|---|---|---|

| GI | Cr-free, Chromated | Corrosion Resistance |

| GA | Slidable Pre-Phosphate (SP) Cr-free, Chromated, Cr+³ | Lubrication Corrosion Resistance |

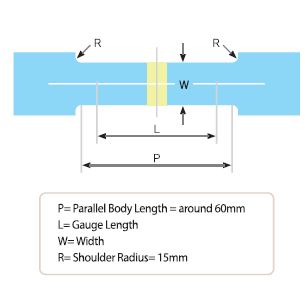

A tension test is a basic testing method to measure the yield point, the tensile strength and the elongation of a steel sheet. In case of a usual tension test, some load is increased until the test piece is broken while some load is added to a fixed test piece.

The kind and sizes, etc. of testpieces are specified in all of the specifications, such as KS, JIS and ASTM, etc. in order for you to prepare for a test piece to be used for a tension test. In case of a cold-rolled stell sheet, a way of selecting a test piece, which is specified in KS B 0801 No.5, is generally used.

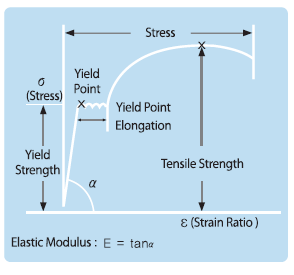

Results from a Tension Test

The results from a tension test are used as the most basic standards to judge the workability and formability.

Higher the elongation is, better the formability.

Lower the elongation is, better the formability.

Yield Ratio =Yield point / Tensile Strength, YR

Lower the yield ratio, wider the gap between the yield point and the tensile strength, and wider the gap is, better the shape freezing property of steel sheet is, when it is processed at the same strength level.

An elastic modulus is inversely proportional to the inverse elasticity of a steel sheet. Lower the inverse elasticity, better the shape of a final product.

When some stress is put onto materials, a deformed part becomes hard in order for it to be constrained not to be deformed more and the force of deformation is for it to be constrained not be deformed mor and the force of deformation is spread to the other un-deformed more and the force of deformation is spread to the other un-deformed parts in order for the whole parts of a material to be deformed evenly. Since bigger the hardening exponent, quicker and evener the spread of deformation, such kind of material considered as the one with a good formability.

In wo/w / In to/t (/wi, w=width before and after a test, and to,t=thickness before and after)

The reduction ratio of the part in the thickness-wise direction is inversely proportional to the value, r, and the reduction ratio of the part in the width-wise direction is proportional to the value r. and bigger the value, r, the harder a steel sheet is cracked and the easier the steel sheet is worked.

The coating weight and adhesiveness tests are done after sampling some test pieces from the top and bottom of each coil.

It is judged with the average value calculated by measuring the coating weights on the back side of three areas width wise, by using an X-ray dry analysis method.

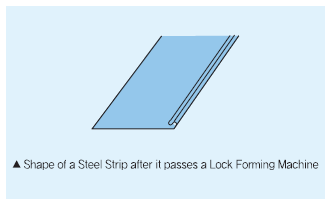

After conducting a lock forming test, the plated status of the deformed area should be checked with the naked eye.

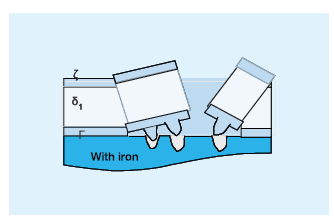

There are layers after zinc coating; due to the shearing stress, the layers get distured. Too much alloy too much shearing stress. If the detachment is more from gamma layer, it is called flaking. Behavior of material when subjected to the shearing stress is known as flaking.

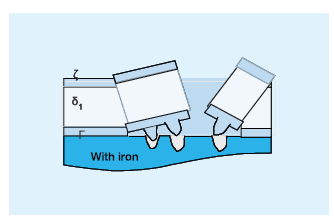

There are layers after zinc coating; due to the compressive stress, the layers get disturbed. Too much alloy too much compressive stress. If the detachment is more from Delta layer, it is called powdering. Behavior of material when subjected to the compressive stress is known as powdering.

Commercial Steel

Used for General Purposes In Manufacturing such as

Structural Steel

Structural Steel does not need drawability but requires high strength

High Tensile Strength Steel

Used where high strength with good formability is required

Extra Deep Drawing Steel

Used where deep drawing quality is required