Cold Rolled Continuous Annealed Steel Coils and Sheets (CR) have fine surface and excellent workability. They are used for various purposes including automobiles, home appliances, furniture, office equipments, Drum, Barrels industrial machines and construction material. Due to economic development and the advancement in consumer's level, the customer are gradually requiring high quality of diversified and functionalized products. We POSCO Maharashtra are making our best effort to satisfy the customers with the optimum quality and continous improvement in our products.

POSCO Maharashtra have state-of-the-art Tandem Cold Rolling Mill and Continuous Annealing Line (CAL) which manufactured drawing, deep drawing, Interstitial free, high strength, AHSS, hot press forming steels which are then confirmed with various international standards such as IS, JFS, JIS, ASTM, EN/DIN, KS Etc.

| Classification | POSCO Maharashtra Pickling Line & Tandem Cold Rolling Mill (PL-TCM) | |||

|---|---|---|---|---|

| Date Of Operation | June, 2014 | |||

| Capacity (Ton/year) | 1,800,000 | |||

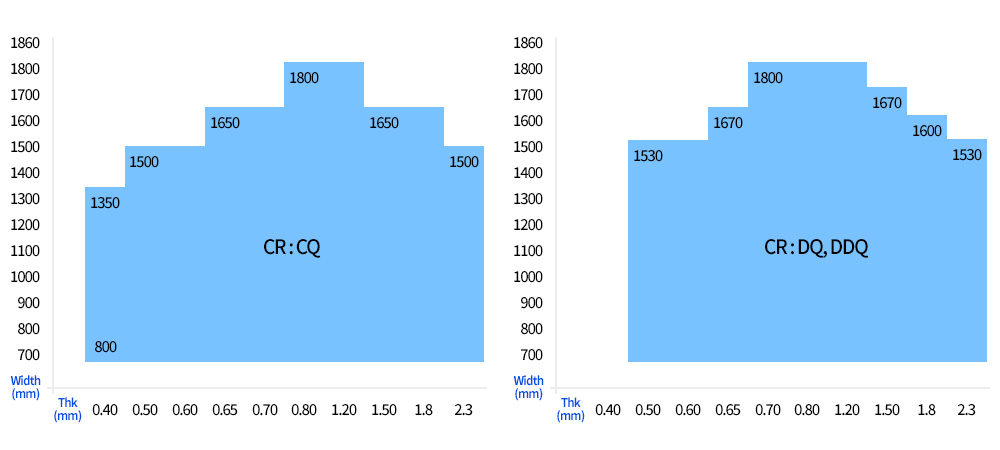

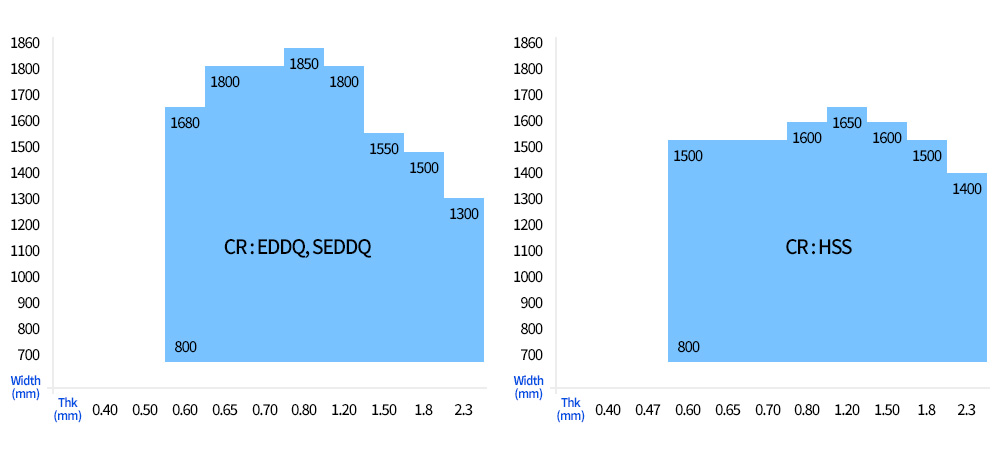

| Available Size | Thickness (mm) | 0.20~2.30 | ||

| Width (mm) | 800~1,880 | |||

| Weight (Ton) | Max 35 | |||

| Product Grade | Commercial, Drawing, Deep Drawing, Extra Deep Drawing, Structural, High-strength Steel, AHSS (DP590 & DP780), Hot Press Forming (HPF1470) | |||

| Inner Diameter (mm) | 508(20”)/610(24") | |||

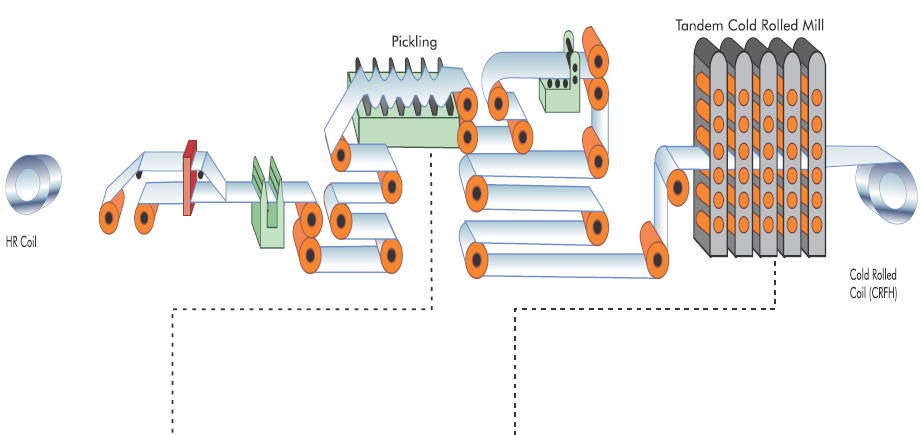

The hot-rolled coil passes through the pickling line, where hydrochloric acid solution is used to remove surface scale for its smooth surface finish before further processing.

Cold Rolling mill is of 6Hi Mill with 5 stand. Pickled coils are rolled in to the as normal as temperature (under of the re-crystallizing temperature) in the tandem cold rolled mills where they are processed into a specified thickness.

| Classification | POSCO Maharashtra Continuous Annealing Line (CAL) | |||

|---|---|---|---|---|

| Date Of Operation | June, 2014 | |||

| Capacity (Ton/year) | 1,000,000 | |||

| Available Size | Thickness (mm) | 0.40~2.30 | ||

| Width (mm) | 800~1,860 | |||

| Weight (Ton) | Max 35 | |||

| Product Grade | Commercial, Drawing, Deep Drawing, Extra Deep Drawing, Structural, High-strength Steel, BH, AHSS (DP590 & DP780), Hot Press Forming (HPF1470) | |||

| Inner Diameter (mm) | 508(20”)/610(24") | |||

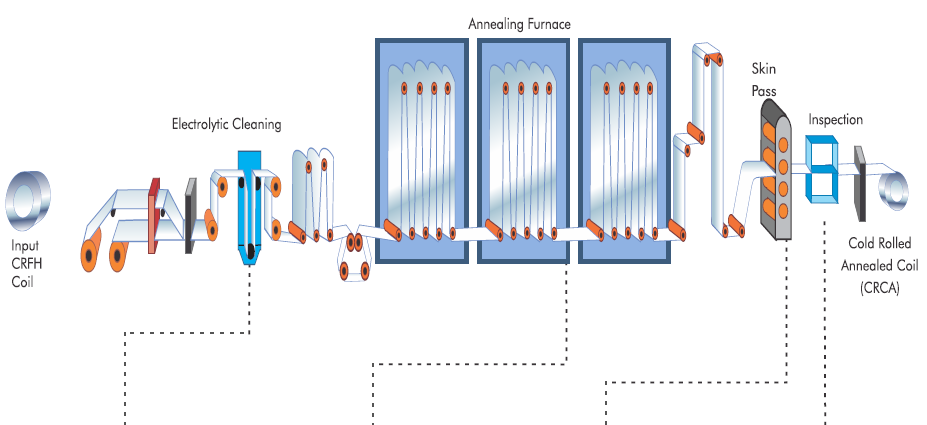

the main purpose of Electrolytic cleaning is to be remove in the lubricant oil and dirts left on the cold rolled strip before annealing.

To obtain the desired grain structure and to improve the mechanical properties, the strip is passed through the (continuous annealing line) furnace, heating, soaking and cooling sections.

In order to improve the mechanical properties, suppress yield point elongation strip shape correction to secure the flat shape, is to be obtain desired roughness, the steel sheet should be passed through a skin pass mill.

The equipment at the exit section are composed surface defect detector, Inspection table and oiler equipment. The products are inspected as well as judged systematically, and whether such products are appropriate to a client company or not.

The products are composed of various metal components and have various mechanical properties in accordance with design standard, depending on various sizes and uses, such as CQ,DQ, DDQ, EDDQ, Structural steel,HSS, AHSS and so forth.

| Classification | POSCO Specification | EN | JFS | Characteristic | Application |

|---|---|---|---|---|---|

| Commercial Quality (CQ) | CSP1 | EN-DC01 | JSC270C | Used for the parts requiring bending & simple forming | Refreigerator Doors, Drums, Furniture |

| CSP1D | EN-DC03 | - | |||

| Drawing Quality (DQ) | CSP2 | EN-DC04 | JSC270D | Suitable for drawing parts | Automotive parts, Home appliances drawing parts |

| Deep Draw Quality (DDQ) | CSP3 | EN-DC05 | JSC270E | Used for Deep drawing parts with good Drawability | Roofs, Fenders and Hoods of Automobiles |

| CSP3N | EN-DC05 | JSC270E | Non Ageing quality used for Deep drawing parts with good Drawability | ||

| Extra Deep Draw Quality (EDDQ) | CSP3E | EN-DC06 | JSC270F | Ultra Low Carbon Steel with excellent deep draw quality | Side Panels, Quarters of Automobiles, Fuel Tanks Automobiles |

| Super Extra Deep Draw Quality (S-EDDQ) | CSP3X | EN-DC07 | JSC260G |

| Grade | 0.2% YS, Mpa Spec. Max |

TS, Mpa Spec. Min |

El % Spec. Min |

|---|---|---|---|

| CQ | 280 | 270 | 33 |

| DQ | 240 | 270 | 37 |

| DDQ | 210 | 270 | 41 |

| EDDQ | 180 | 270 | 43 |

| S-EDDQ | 160 | 260 | 45 |

| Classification | POSCO Specification | EN | JFS | Characteristic | Application |

|---|---|---|---|---|---|

| Bake Hardening Steel (BH) | PCY180B | HC180B | JSC270H | This is high strength material in which yield strengh is increased after baking to become more dent resistance & higher formability | Automobile Outer panels like Hoods & Doors |

| PCY210B | HC220B | JSC340H | |||

| HSLA (High Strength Low Alloy Steel) | CHSP260Y | HC260LA | - | This is High Strength Material manufactured by adding precipition hardening elements such as Ti, Nb to Low Carbon Steel. | Kinds of Member-Reinforcing Materials |

| CHSP300Y | HC300LA | - | |||

| CHSP340Y | HC340LA | - | |||

| CHSP380Y | HC380LA | - | |||

| CHSP420Y | HC420LA | - | |||

| Rephosphorised Steel | CHSP35R | HC220P | JSC340W | This is high strength steel manufactured by adding alloying elements such as Phosphorus (P) and Manganese (Mn). | Cowl, Wheel Appron, Front Side member |

| CHSP40R | HC260P | JSC400W | |||

| CHSP45R | CHSP45R | CHSP45R | |||

| IF HSS Steel | CHSP35E | HC180Y | JSC340P | This is ultra-low carbon steel with special elements such as Ti added. Used in automobile for high strength and deep drawability. | Outer Panels of Doors, Hoods and Fenders, etc. |

| CHSP40E | HC260Y | JSC390P | |||

| CHSP45E | - | JSC440P | |||

| Dual Phase (DP) | CHSP60DP | HCT590X | HCT590X | This is high strength and high formability properties by its dual phase structure consisting of micro ferrite & martensite. | Kinds of Member-Reinforcing Materials |

| CHSP80SP | HCT780X | JSC780Y | |||

| Hot Press Forming Forming (HPF) | PCT1470H-B | - | - | This is high strength steel achived by heating and quenching. Additional hardenability due to addition of Boron | Automotive A pillar, B pillar, C pillar, Bumpers, etc. |

| Classification | Posco Specification | Guaranteed Value | 0.2% YS, Mpa Spec. |

TS, Mpa Spec. |

El % Spec. Min |

YS Min (Mpa) | TS Min (Mpa) | EL Min % |

|---|---|---|---|---|---|---|---|---|

| Bake Hardening Steel | PCY180B | YS | 180-240 | 270 min | 40 | 180 | 270 | 40 |

| PCY210B | YS | 210-270 | 340 min | 36 | 210 | 340 | 38 | |

| HSLA (High Strength Low Alloy Steel) | CHSP260Y | YS | 260-340 | 350-430 | 28 | 260 | 350 | 28 |

| CHSP300Y | YS | 300-380 | 380-480 | 22 | 300 | 380 | 22 | |

| CHSP340Y | YS | 340-440 | 410-530 | 18 | 340 | 410 | 18 | |

| CHSP380Y | YS | 380-500 | 460-600 | 18 | 380 | 460 | 18 | |

| CHSP420Y | YS | 420-530 | 490-600 | 16 | 420 | 490 | 16 | |

| Rephosphorised Steel | CHSP35R | TS | 187 min | 340 min | 34 | 187 | 340 | 32 |

| CHSP40R | TS | 236 min | 390 min | 29 | 236 | 390 | 29 | |

| CHSP45R | TS | 275 min | 440 min | 28 | 275 | 440 | 25 | |

| IF HSS Steel | CHSP35E | TS | 175 min | 340 min | 34 | 167 | 340 | 32 |

| CHSP40E | TS | 215 min | 390 min | 30 | 206 | 390 | 27 | |

| CHSP45E | TS | 255 min | 440 min | 27 | 245 | 440 | 27 | |

| Dual Phase | CHSP60DP | TS | 340-450 | 590 min | 20 | 450 Max | 590 | 24 |

| CHSP80SP | 450-550 | 780 min | 16 | |||||

| Hot Press Forming | PCT1470H-B | TS | 300-600 | 500-700 | 13 | 320 | 550 | 15 |

| Thickness/Width | 800≤w<1,000 | 1,000≤w<1,250 | 1,250≤w<1,600 | 1,600≤w≤1,800 |

|---|---|---|---|---|

| 0.30≤t<0.40 | ±0.040 | ±0.040 | - | - |

| 0.40≤t<0.60 | ±0.050 | ±0.050 | ±0.060 | - |

| 0.60≤t<0.80 | ±0.060 | ±0.060 | ±0.060 | ±0.070 |

| 0.80≤t<1.00 | ±0.060 | ±0.070 | ±0.080 | ±0.090 |

| 1.00≤t<1.25 | ±0.070 | ±0.080 | ±0.090 | ±0.110 |

| 1.25≤t<1.60 | ±0.090 | ±0.100 | ±0.110 | ±0.130 |

| 1.60≤t<2.00 | ±0.110 | ±0.120 | ±0.130 | ±0.150 |

| 2.00≤t≤2.30 | ±0.130 | ±0.140 | ±0.150 | ±0.170 |

(Unit : mm)

| Thickness/Width | Width | Tolerances Using Cold Rolled Steel Sheet |

|---|---|---|

| Mill Edge | Under 1,250 | +7,0 |

| 1,250 and Over | +10,0 | |

| Slit Edge | Under 1,250 | +3,0 |

| 1,250 and Over | +4,0 |

(Unit : mm)

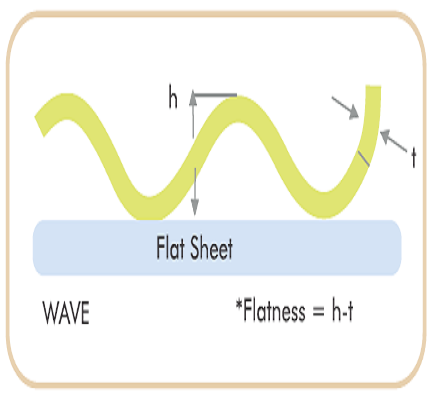

| Classification | Wave (Number of Waves) |

Edge Wave (Height) |

Center Wave (Height) |

|

|---|---|---|---|---|

| Width | ||||

| Under 1,000 | 2 | 2 | 2 | |

| 1,000 and over and under 1,250 | 3 | 2 | 2 | |

| 1,250 and over and under 1,600 | 4 | 3 | 3 | |

| 1,600 and over | 5 | 4 | 4 |

Notes :

1. Flatness is measured on a flat table as side drawing. Flatness which is applicable to upper side of the steel is the value except thickness of the steel is the value from the maximum value of transformation.

| Classification | Specification |

|---|---|

| Dull Finish | Dull finish, which is attained by attaching numerous fine grains onto the steel surface, is often called 'pear-skin finish' or 'egg-shell texture'. The grains are made by electro discharge texturing machine. The dull finish is usefull in drawing because lubricant oil can be evenly spread over the entire surface, thereby reducing the possibility of friction. The fine grains also help to boost paint adherence and extend the steel life span of the steel. |

| Dull Finish Ra (μm) | ||

|---|---|---|

| E5 | E7 | E9 |

| 1.00~1.80 | 0.70~1.30 | 0.40~0.80 |

It is recommended that customers use product promptly to avoid the possibilities of rusting during storage or shipment Customer can choose kind of oil and quantity. Oiling improves corrosion resistance but cannot be the perfect way to protect steel from rust. Also, non-oiled and DOS oiled products are easy to rusting so, POSCO Maharashtra strongly recommends to apply general oil and use the product as soon as possible.

| DuClassification | Quantity (Mg/m²) (Both Sides) |

|---|---|

| Heavy | 3,000~4,500 |

| General | 1,800~3,000 |

| Light | 800~1,800 |

| Thin | 200~800 |

| DOS - D | 50~100 |

| DOS - S | 20~50 |

| DOS - U | 10~20 |

Commercial Steel

Used for General Purposes In Manufacturing such as

Structural Steel

Structural Steel does not need drawability but requires high strength like

High Tensile Strength Steel

Used where high strength with good formability is required

Extra Deep Drawing Steel

Used where deep drawing quality is required